|

NEW RESEARCH VESSEL R/V "KRISTINE BONNEVIE" - MGG CONSIDERATIONS

Project description

| UNIVERSITY OF BERGEN

Department of Earth Science

Allé gt. 41, N-5007 Bergen, Norway

|

|

|

|

|

|

|

|

|

| 0.1

| DRAFT - request for comments

| -

| 26 March, 2018

| OM

| OM

| -

|

| VER.

| STATUS

| CHANGE

| DATE

| BY

| CKD

| APPD

|

RV "Kristine Bonnevie", 23 November 2016. Click to enlarge.

This web page presents University of Bergen considerations related to Marine Geology & Geophysics (MGG) on the new research vessel "Kristine Bonnevie". Planning is done jointly with University of Tromsø, Department of Geology who is also involved in a broad range of MGG activities (mainly based on RV "Helmer Hansen").

| RV "Kristine Bonnevie" - Principal Particulars

|

| Length overall:

| 56.75 m

|

| Length between perpendiculars:

| 48.55 m

|

| Breadth:

| 12.50 m

|

| Frame spacing:

| 0.55 m

|

COMPRESSED AIR - HSE CONSIDERATIONS

Accident report: IAGC [International Association of Geophysical Contractors]: "Hi Pressure incident 2011"

COMPRESSOR CAPACITY - REQUIREMENT

| Who

| Conf. no.

| Survey type

| Desired pressure

| No. and type of airguns - volume

| Firing rate

| Equivalent flow rate

|

University of Bergen

Dpmt of Earth Science

| 1

| Refraction

| 138 Bar (2000 psi)

|

- 4 ea Bolt mod. 1500 airguns

- Each airgun chamber volume 1200 inch3 = 19.66 liter1)

- In total 4800 inch3 = 78.7 liter

| Firing every 200 meter, with max ship speed 6 knots, gives firing rate of 200/(6*1852/3600)

= 65 s

| (78.7 liter / 65 s) = 1.21 liter/s =

72.6 liter/min @ 138 Bar

|

| 2

| Reflection

| 138 Bar (2000 psi)

|

- 4 ea Bolt airguns with various chamber sizes

- Total volume (typ.): 766 inch3 = 12.55 liter

| Firing every 50 meter, at max speed 6 knots, giving shot interval of

50/(6*1852/3600) = 16.2 s

| (12.55 liter / 16.2 s) = 0.77 liter/s =

46.5 liter/min @ 138 Bar

|

| 3

| Reflection

| 138 Bar (2000 psi)

|

- 4 ea Bolt airguns with various chamber sizes

- Total volume (typ.): 766 inch3 = 12.55 liter

| Firing every 25 meter, at max speed 6 knots, giving shot interval of 8.1 s

| 1.55 liter/s =

93.0 liter/min @ 138 Bar

|

University of Tromsø

Geology Dpmt

| 4

| Reflection

| 200 Bar (2900 psi)

| 1 airgun, 30 inch3 volume = 0.492 liter

| 3 s shot interval

| (0.493 liter/3s) = 0.164 liter/s =

9.9 liter/min @ 200 Bar

|

| 5

| Reflection

| 200 Bar (2900 psi)

| 1 airgun, 420 inch3 volume = 6.883 liter

| 41 s shot interval

| (6.883 liter/41s) = 0.168 liter/s =

10.1 liter/min @ 200 Bar

|

1) Conversion from cubic inch to liters - this online converter is used.

- Cubic Feet per Minute = CFM = ft3/minute at actual conditions

- Standard Cubic Feet per Minute = SCFM = ft3/minute at standard conditions (1 atm = 14.7 psi, 68°F = 20°C )

"Worst-case" configuration --- no. 3

"Worst case" equivalent flow rate is thus 93 liter/min (3.284 cf/m) @ 138 Bar (2000 psi).

This is equivalent to 450 SCFM (where SCFM = Standard Cubic Feet per Minute = ft3/minute at standard conditions 1 atm = 14.7psi, 68°F).

OBS-survey configuration - no. 1

These basic and derived parameters are needed to estimate required compressor capacity:

- Airgun array volume: 4 ea Teledyne-Bolt model 1500, each 1200 inch3, in total 4800 inch3 (2.778 ft3)

- Shot point interval distance: 200 meter

- Nominal airgun pressure when firing: 138 Bar (2000 PSI)

- Vessel survey speed: 5 knots (2.57 m/s) -- which yields (200/2.57) = 77.8 seconds firing interval --- speed requirement reduced from 6 kt.

- A theoretical approach: A geometric airgun volume of 2.778 ft3 must thus be supplied with air at standard atmospheric conditions, 138 times this geometric volume, every 77.8 second - that is 383 ft3 every 77.8 second, equivalent to 296 CFM (ft3 per minute).

- In practice, compressor manufacturers use empirical formulas to calculate required capacity. E.g., 250 CFM with our parameters.

Converted to cubic meters: 250 CFM => 7.079212 m3/minute => 425 m3/hour

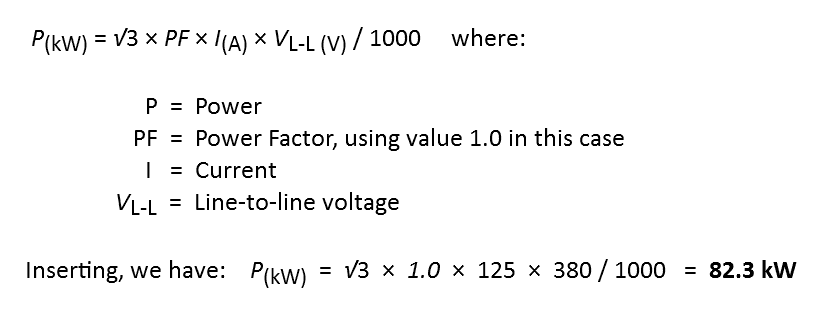

POWER AVAILABLE ON RV "KRISTINE BONNEVIE"

If practical, compressor should have electrical power.

There is 3-phase outlet, 380 V, 50 Hz, 125 A max, on shelter deck. The amount of power available is given by the following expression:

RESERVED CONTAINER LOCATIONS

R/V "KRISTINE BONNEVIE" - reserved locations for 10' containers.

Starboard side, Forecastle deck

Container position Starboard side, facing bow. Click to enlarge.

Container position Starboard side, facing stern. Click to enlarge.

IS IT POSSIBLE TO HAVE CONTAINER LONGER THEN 10 FEET ON STARBOARD SIDE?

Port side, Forecastle deck

Container position Port side, facing stern. Click to enlarge.

COMPRESSOR SPECIFICATIONS - preliminary

- Capacity: 375 CFM at 2000 PSI (138 Bar).

- Compressor should be containerized.

- Container should include high pressure storage bottles, control valve and blow off silencer.

- Electrical or diesel powered (will be determined at later stage).

- Compressor can be monitored and operated remotely, from vessel instrument room.

- To be determined: Location of pressure sensor (for monitoring HP output pressure) and distribution of this sensor signal.

- IP interface to facilitate remote diagnostics and service

COMPRESSOR MANUFACTURERES

Sauer compressor

Click to visit SAUER Compressor rental web page.

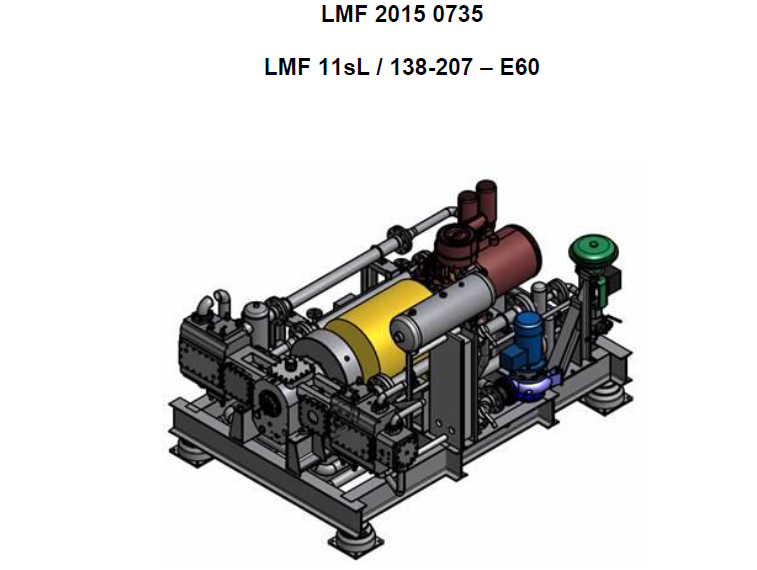

LMF compressor

A request has been sent to LMF for a technical solution and a quotation regarding a mobile system for a compressor used for marine seismic operation. The main requirement is constrained by the capacity which should be at minimum 10.4 m3/min free air, corresponding of the current compressor on R/V Håkon Mosby.

The technical answer proposed by LMF is:

High Pressure Compound Compressor LMF 11sL/138-207 E60

Piston Compressor BS102-309 S21

A capacity of 11 m3/min (390 cfm) and a discharge pressure of 138 barg (2000 Psig) or 207 barg (3000 psig). [Using atmospheric pressure as reference is usually signified by a "g" for gauge after the pressure unit.]

LMF compressors

Overall compressor Unit Data:

| Power consumption: | main consumer | aux. consumer |

|---|

| Screw/piston Compressor | 208 kW |

|---|

| Cylinder lubrication | | 0,25 kW |

|---|

| Compressor control system approx. | | 3,00 kW |

|---|

| Oil heater piston compressor | | 1,00 kW |

|---|

Voltage / frequency for auxiliary drives and control system suitable for 380 V/50 cps

or 440 V/60 cps

| Seawater inlet/outlet temperature max. | 35°C / 40°C |

|---|

| Seawater consumption approx. | 25 m3/h |

|---|

| Required freshwater inlet pressure | 2 bar g |

|---|

Dimensions and Weights

| Compressor unit dimensions (in m) |

|---|

| Length incl. sea/freshwater heat exchangers (plate type) | approx. 2,8 |

|---|

| Width | approx. 2,3 |

|---|

| Height | approx. 1,7 |

|---|

| Compressor unit weight | approx. 9,5 to |

|---|

| Control cabinet dimensions (in m) |

|---|

| Width | 0,8 |

|---|

| Depth | 0,6 |

|---|

| Height | 2,2 |

|---|

| Control cabinet weight (in to) | 0,4 to |

|---|

Granzow AS

Seamap

Wärtsilä Hamworthy Seismic Compressors

Atlas Copco

DIESEL FUEL TANK FOR COMPRESSOR

A compressor with diesel motor would require fuel tank of, say, 2 m3, to keep it running for 24 hours, before resupply would be necessary. Such fuel tanks can be of type shown below. They could be placed upon container that houses compressor - provided vessel structural strength and stability concerns are adressed first.

- Seismic compressor, containerized, with diesel drive: Search for "clean diesel fuel lines dnv"

- 8 feet Fuel containers:

Example 4000 liter Heli-fuel tank, manufactured by Hoover Ferguson

|

Example 2900 liter Heli-fuel tank, manufactured by Hoover Ferguson

|

DNV certified tanks from MODEX: Model "TC20 2000L Vertical Chemical" could be considered ..... Quote: "MODEX is a leading manufacturer and provider of DNV certified CCU’s [= Cargo Carrying Units], cabins and well service equipments for offshore oil & gas operations."

|

CONTAINER FOR SEISMIC RECORDING

(For later consideration.)

MAGNETOMETER WINCH FOUNDATION

(For later consideration.)

MEETING WEEK 17/2017 - CLARIFICATION OF TECHNICAL ISSUES

Agenda

- Adherence to relevant standards?

Should this delivery be in compliance with NORSOK Z-015 "Temporary equipment" (Rev. 4, September 2012) ?

Which parts (if any) of the compressor / HP air system should be subject to inspection & approval by e.g. DNV?

(To indicate risks associated with HP air, here is accident report issued by IAGC (International Association of Geophysical Contractors): "Hi Pressure incident 2011"

- Report from IMR regarding placement of 10 feet / 12 ton container compressor on board RV "Bonnevie".

- If and how lay-out of compressor container should be influenced (if possible) by its location on board. Could affect position of:

- Operator interface.

- Manifold for HP air distribution (we assume manifold is furnished with valve and manometer for all outputs, and input).

- Over-pressure valve ("Fisher" valve) which must be accessible for adjustments.

- Cooling water connection point.

- Diesel fuel connection point.

- Connection point for signal cable (for remote control and monitoring).

- Supply of diesel fuel:

- Pipe or hose interface: Threading type / dimensions.

- What is estimated diesel fuel consumption at max HP air capacity 375 CFM.

- Recommended volume of diesel tank within container.

- Is filter on diesel feed line required.

- Regarding HP air:

- Number of manifold outlets? (At least 4 ea).

- Install oil / water filter in HP outlet?

- How compressor can be operated and monitored from vessel instrument room.

- Location of HP air pressure sensor, and distribution of signal from this unit.

- Cooling water requirements:

- Salt / freshwater.

- Flow rate [m3/hour].

- Pressure range.

- Max allowed temperature (of relevance if compressor container used on research vessels operating in tropical waters).

- Pipe / hose interface: Threading type / dimensions.

- IP-connection to internal compressor instrumentation system, permitting factory remote diagnostics and error location ?

- Service requirement, both of diesel engine and compressor. Service agreement: Scope, terms and cost?

- Recommended set of spare parts.

- Required operator qualifications or certifications ?

- This LMF brochure "LMF high-pressure oil-free compressor for offshore seismic exploration" mentions new oil free compressor type (eliminating oil contamination of HP air; and the need for change and disposal of used oil). Is this compressor type relevant for our application?